Electronics And Electricals

Are You

looking for a good SMT & PCB designing supplier who can do SMT mounting in low quantity but is unable to evaluate properly?

facing quality issues in circuit & PCB products or delivery issues with your SMT & assembly supplier?

losing the market share you deserve due to poor quality of electronic parts?

Do You Face Challenges

with field failures from your customers or frequently replacing electronics parts causing financial and reputational issues?

of delays in product launch due to late or small quantity or poor-quality delivery by the supplier and have to spend time and energy in following-up?

with suppliers not understanding product specifications and delivering wrong and inconsistent quality products?

J4S Alliance is the industry leader and provides various processes such as electronic, wire harness, ultrasonic under one-roof.

Capacity

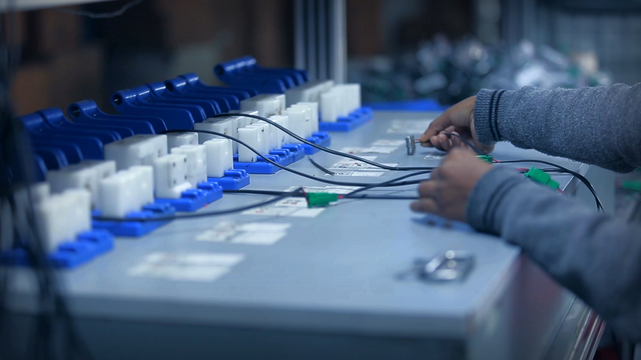

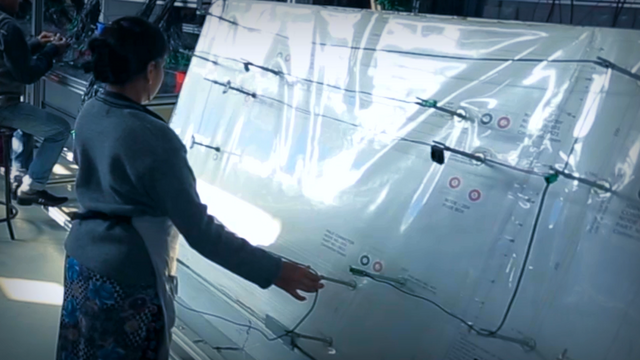

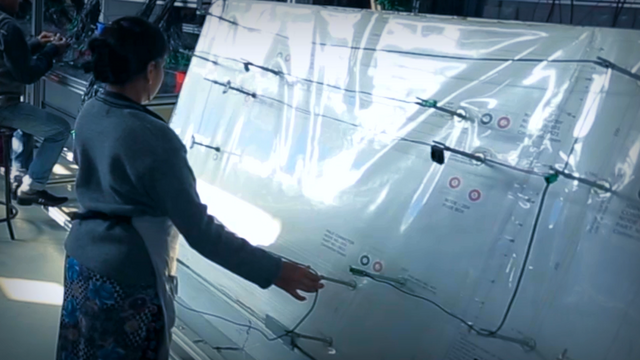

Multiple product assembly lines and advanced machines to produce a wide variety of electronic, electrical, and mechanical products.

Facilities include tabletop SMT machine, component mounting on PCB, ESD safe electronics assembly line, wire harness design & dev facility, advanced press machines for SS/MS components, advanced plating on plastic, painting shop, powder coating facility, etc.

2600W, 5 Ultrasonic machines for waterproof welding and housing of electronic circuit; 1000W, 8 ultrasonic machines (handgun) for electrical and mechanical parts; 60 to 1000 tons moulding machine to mould any type of plastic parts for electronics assembly

Quality Controls

IATF certified plant with an in-house test lab to test and evaluate products during development and production

for wire harness testing, facilities include profile projector, UTM (for crimping load) laying board, micrometer and circuit testing with Poka-Yoke.

Strong process audit function for ensuring desired quality and QA system to eliminate in-process rejection

Skilled Staff

A well-qualified, trained, and dedicated team with average 10+ years’ experience in both automotive and non-automotive product design and development, PCB & circuit design, tool design, tool engineering, mould engineering, surface finishing engineering, and project management.

Qualified QA engineers, with a combined experience 50+ years, in electronics, wire harness, and mechanical parts development.

Electric Vehicle

Automobile Accessory

Harness